We've made a Google Map of the places that serve and/or sell our coffees.

With this and the links in the right column of this blog it should make your search for some TCC coffee an easier task.

Vis The Coffee Collective på et større kort

Monday, August 30, 2010

Google Map of The Coffee Collective

Indsendt af

Klaus Thomsen

1 kommentarer

![]()

Friday, August 27, 2010

Copenhagen Cooking

This week the Nordic food festival Copenhagen Cooking is taking place here in our fair city.

We'll be part of it trying to expand people's horizon on what coffee can be.

At Taste The World 25 top restaurants will be showcasing their cuisine, amongst them Michelin star Vietnamese restaurant Kiin Kiin. We will be there serving single cup Hario V60 filter drip of three of our selected coffees.

You can find us on Nørrebrogade between Sortedams Dosseringen and Fælledvej. It's an outdoor event, so admittance is free.

We are also going to be present at the first Danish Food Blogger Symposium held at Nordatlantens Brygge. 84 of the country's most serious food bloggers will meet for a full day of lectures covering subject ranging from web journalism over photography to gastronomic trends. We're happy to sponsor the event and look forward to serve some great coffee. Claus Meyer, Anders Selmer and Katrine Klinken are some of the people, who will be there, so we look forward to some interesting talks.

Indsendt af

Klaus Thomsen

0

kommentarer

![]()

Thursday, August 19, 2010

Daterra 2010 visit part 3

See part 1 here or 2 here

After harvest the coffee cherries arrives at the Wet Mill receiving station where it undergoes several sortings already.

The over-ripe Raisins are separated from the unripe green and fully ripe red or yellow cherries in a floater – the overripe stays on top of the water and the others fall to the bottom. From there they are each processed differently. The Naturals will go through a size sorting and then straight to the patio for sun-drying.

The green and ripe cherries go to a series of de-pulpers. Here’s an important selection already happening. The first machine only applies a very low pressure thus depulping only the ripest cherries. This coffee will go to a lot like the Sweet Collection. The next machines adds a little more pressure and that will be for another class of coffee. The last applies a lot of pressure depulping green cherries too, and that coffee will not even be sold as a Daterra coffee.

Freshly pulped coffee

The pulp is then removed and used for compost, which is a very rich fertilizer. The coffee goes through a series of water tanks (water is used in most of these machines for transporting the beans around) where very lightweight beans are sorted out. After that they are put to the drying patio.

In all this Daterra keeps strict control of each lot and can trace it back the whole way through the system, even when it’s been divided into several qualities. At each wet mill there’s a Lab where each lot is cupped and logged.

Drying is essential in getting the right quality. Daterra begins with sun drying on huge patios and then finish with a mechanical drying. This year however, the weather has been extremely dry and warm, so a lot of the Naturals have dried so quickly on the patio that no machine drying was needed. The drying machines are basically like big tumble driers, made to run on steam. But Daterra just use hot water and dries at a much lower temperature than most. They find that a faster drying damages the beans resulting in a duller, flatter flavour in the end.

Some Naturals drying

After drying to a moisture content of 11,5% the beans, still inside their parchment, needs to rest for at least 30 days for the moisture to settle throughout the bean and throughout the entire lot. I had some talks with Daterra about whether or not this is really necessary as the beans will rest in the month it almost takes for the container to make it from the farm to us in Copenhagen. But they stressed that they need to rest in the parchment to develop correctly and that without the resting you might see big variances within the same lot from bag to bag.

After the Reposo, as the resting period is called, the coffee goes to the Dry Mill. Usually a farm doesn’t have their own dry mill. Finca Vista Hermosa in Guatemala gets the dry milling done at whatever dry mill Edwin thinks is the best that year and in Kenya the wet mills are usually part of a coop that owns a dry mill. But since Daterra is not your usual farm, or your usual size, they have their own dry mill. And it is state-of-the-art.

First foreign material such as twigs and stones are removed. Then the parchment or husk is hulled and removed. Next is the screen sorting, where the coffee is sorted by bean size. Each bean size will be a different quality and now we again have several selections of the same lot. The each of those sizes are put through a density separator, so that a given sized bean also has a given weight.

The last part is perhaps where Daterra sets itself apart from others. Electronic sorting machines are seen in more and more dry mills. They work by “looking” at the color of the beans and rejecting beans that fall out of a set range. They are amazingly effective and can sort up between 5.000 and 10.000 beans pr second! That’s not a typo.

But Daterra found out some years ago that beans that are not fully ripe will reflect differently in Ultraviolet light. They have then developed an electronic sorting machine, based on a machine made for blueberries, that sort with this. It’s extremely funny to watch a portion of green coffee that looks completely uniform, and then watch it again under UV light.

After passing through three different electronic sorting machines the coffee is finally ready to be packed and shipped. Daterra has a special temperature- and humidity-controlled warehouse to store the coffee in before and after packaging.

And then of course there’s the Penta boxes. Daterra was the first farm in the world to start with nitrogen-flushing and vacuum packing their green coffee. By now lots of other farms are following suit and many of the best specialty roasters refuse to store coffee in jute sacks.

The last part is then cupping.

The most important part for me.

I had a tremendous time cupping with Carlinhos at the Daterra Coffee Quality Lab. They even had a 2-group La Marzocco FB80 there, so I could make espressos for everyone and feel a bit like home. We also cupped some of The Coffee Collective’s roasts, our Daterra Sweet Collection from last year and our two new Kenyans.

Andreza and Carlinhos discussing which they like better; Gatina or Kieni. But of course that yellow one in the front won.

On my last day at the farm I was joined by Luís, the owner of Daterra, and George Howell of Terroir Coffees in Boston MA. If you don’t know who he is then you probably don’t work in coffee. The man’s a legend. I was fortunate to spend a few days with him after the farm visit and it was truly inspiring. My colleague Mads from Estate Coffee also came with them and it was fun to be more visitors to the farm.

Luís introducing a cupping session

We also visited the Instituto Agronômico de Campinas with Leo. His friend and fellow agronomist and researcher Guerreiro showed us around. They do a lot of crossing of plants and research into varieties. There’s a lot just outside with many differenct species and varieties of coffee trees. It was very impressive! Some didn’t look like coffee trees at all but had fruit you could tell was coffee. Others had fruit that looked totally different, but sure enough, inside was coffee beans.

And then there's the Robusta which demonstrates why it's so much easier and cheaper to grow:

I must admit I didn’t know of other species besides Coffea Arabica, Canephora (Robusta) and Liberica, but I think they showed me 4 or 5 others. And then a whole bunch of arabica varieties and cultivars too. Very enlightening and I thank Guerreiro for the tour and for explaining me how crossing is done (I’ll save that for another time though).

George Howell and agronomist Guerreiro

On the last day with Daterra we held an event for Brazilian media and coffee people at Ateliê do Café. It was a very cozy yet professional event and I had great fun pulling shots for people. We also go to taste George’s Terroir North Italian roast of Daterra, next to Ateliê do Café’s and our Daterra Sweet Collection Espresso.

Now the coffee is still getting the final reposo at the farm. Then it’ll be dry milled and packaged. So it’s still several months till this coffee is good to be shipped to us. We’re looking forward already. The samples we got back home shows lots of promise and we’re already looking forward to going again next year. Probably it’s Linus’ turn to go then.

Thanks to everyone at Daterra for showing such amazing hospitality and sharing every aspect of your work. I am deeply impressed in the openness and honesty that everyone at the farm showed. We really appreciate buying directly from Daterra and being able to visit every year. See you soon again!

Indsendt af

Klaus Thomsen

3

kommentarer

![]()

Wednesday, August 18, 2010

Daterra 2010 visit part 2

Daterra 2010 visit part 2

See part 1 here

Daterra grows several varieties – or cultivars to be accurate: Mundo Novo, Bourbon, Catuaí, Icatú and Acaiá, and several of these in both red and yellow varieties. Besides those there’s also some experimental cultivars, amongst those the Aramosa, which is a low-caffeine crossing of the species Arabica and Racemosa that Daterra was part of developing.

The farm have its own nursery for planting and attending new coffee trees. The sprouting is called “Little Soldiers” from the look of the bean shooting out of the ground.

Gustavo showed me how extremely important it is that the root system grows straight down from the very beginning. Otherwise the roots won't bring the nutrients efficiently to the rest of the tree. The tree will then perform badly and eventually it might die. Here’s a good example of a very bad root.

In average Daterra plants 4.000 trees per hectar. Typically for Brazil the trees are planted in very long rows with sections in between for the harvesting machine to dump the cherries in a truck. I took this picture when we flew back from the farm.

The agronomists on each farm decide when and how to prune the trees; stumping, pruning the sides or simply the top. You loose two to three year’s harvest when you prune, so it’s a careful consideration. I visited a lot where the coffee trees have been allowed to grow wild since 1973 and the trees were now around 4 metres high. Potentially they could grow higher but these ones had started to slant to the sides and in stead increased in the size of the trunk. It was quite fun to see the the size of the trees though and to see the many young coffee trees growing wild underneath from the cherries that had fallen to the ground.

I also visited the lot where we’ll be getting this years Sweet Collection from; Boa Vista 22:

This year the harvesting began quite early due to a very strange flowering last year.

A coffee tree in most areas flower once a year following (heavy) rain fall. The green coffee then ripens for somewhere between 8 to 10 months.

Just a drop of rain and this tree will flower:

Green, unripe cherries:

Around week 30 after the flowering season (meaning flowering is week 0) Daterra collects samples from all the different fields/lots that are then processed, dried, hand sorted, roasted and finally cupped by Carlinhos. From that cupping they decide when the harvesting of each lots should begin. I’ve never before encountered a farm who had this approach to determining the harvest time. It’s very impressive! Most farms will go by the color of the cherries, when deciding when to harvest. I’ve also seen others measure the sugar content and Daterra has also tested this is in the past, but decided not to rely on it. It simply didn’t give results that matched when it was best to harvest from a taste-point-of-view.

Usually the harvest than begins around week 40 after flowering, but this year they had to start already week 31 – just a week after cupping the lots. As I mentioned earlier the flowering this year in Brazil was sort of strange, resulting in very different ripening stages on the same branch.

Harvesting in Brazil is done in most places with machines. The few who do hand picking, usually don’t do selective hand picking of only ripe cherry, but in stead stripping – which is removing everything from the branch. The machines Daterra uses are quite different than the other machines I’ve seen in Brazil. They look the same but functions differently.

The whole machine drives over a row of coffee trees, 2,5-3 metres height I’d guess. Inside there’s many small sticks made out of a bendy material. The sticks vibrate gently and shake off the cherries from the tree. In the past I’ve seen similar machines, but on those the sticks were rotating and thus stripping all cherrys and lots of leaves off the branches. Naturally it’s a bad idea to remove the leaves as you’ll have less photosynthesis happening. With Daterra’s machine I was impressed to see how few leaves were taken off and that no branches while I observed were damaged. The cherries, just like a ripe apple, will fall of quite easily compared to the unripe. So Daterra can actually harvest the same rows 2 or 3 times.

I came at the very end of the harvest season, though, so most of what was left were the Raisins – the over-ripe cherries that become natural processed coffee.

Straight after harvesting the coffee will go to the Wet Mill for processing.

Indsendt af

Klaus Thomsen

2

kommentarer

![]()

Tuesday, August 17, 2010

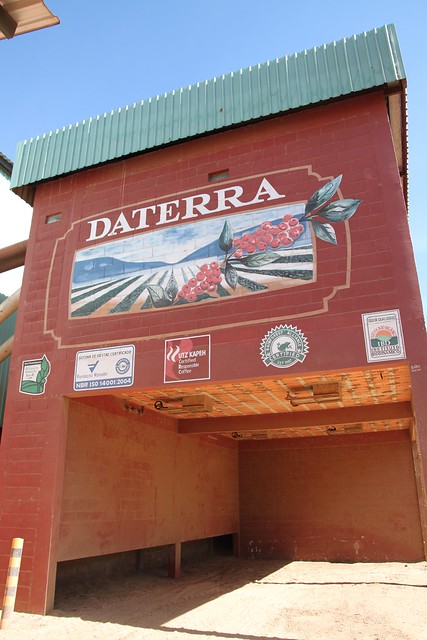

Daterra 2010 visit part 1

When we originally started planning The Coffee Collective, Daterra was the first farm we knew we’d buy from. Back in 2005 when Peter and I was training for the barista championship and developing the blend I was going to use, we visited Daterra and had a true Eureka! moment when we cupped the Daterrra Sweet Collection. It was extremely sweet and clean with a mouthfeel that felt perfect for espresso.

So I was very excited to visit Daterra again this year for the first time since then.

Daterra is located in the Cerrado region. A region you’ll have a hard time finding on a map, since it’s not a political but an ecological region. It’s a very dry area with lots of small Savannah-like vegetation. The farm itself is located around 1100-1200 meters above sea level and measures a whooping 6.000 hectars of land – half of that, though, is actually reservation area, where no coffee is grown. To say Daterra is one farm, is technically incorrect as it is actually made up of three farms: Boa Vista, where the office, the Dry Mill and Quality Control Center is located, Tabuões neighbouring Boa Vista, and finally São João, which is pretty far away in the Sao Paulo state.

There’s about 300 people employed full time year round at Daterra and an additional 150 during the harvest season. I didn’t get to meet them all. But I did get to see Luis Pascoal, the owner and visionary behind Daterra. Luis is an amazing guy whose commitment to sustainable practices and innovation is unsurpassed. He bought the farm 18 years ago and within a decade it was already renowned throughout the specialty coffee world – not the least for it’s research, much of it done together with Illy in Trieste, Italy, specifically on growing and processing coffee for espresso. They were the first farm in the world to vacuum pack coffees in stead of packing in jute sack. Their dry mill have machines that are state-of-the-art and some which Daterra even invented themselves. And to hear Luis speak about politics and environmental challenges almost makes me wish he was a political leader – but then again I’m sure he’s doing plenty good where he is now. Besides the farm Luis is the C.E.O. of Dpaschoal – the largest tire supplier in Brazil. And even in that business he’s committed to environmentally sustainable practices and is right now re-schooling all of his 4.000 employees. Besides that he finds time for a charity fond and even design coffee cups for his roastery Ateliê do Café. The man must never sleep.

Luis and agronomist/farm manager Leo

Daterra was the first coffee farm in Brazil to be Rainforest Alliance certified and today have numerous certifications.

The always lovely Andreza showed me around the farm and in general took great care of me. She’s also the one we talk to about all the logistics and purchases of the coffee. During harvest season and until the coffee has been shipped her calendar must be heavily packed. I’m very grateful for her hospitality!

Carlinhos (“Little Carlos”) is the Quality Control chief and cupper at the farm. He roasts and cups every single microlot before, during and after harvest, constantly monitoring the development. And also he’s a very nice guy! I really enjoyed cupping with him.

Carlinhos and Andreza cupping some TCC coffees

I also met Daterra’s three agonomists. Leopoldo Santana – or just Leo - is really the farm manager and in close cooperation with Carlinhos they’ll determine when to harvest and what to renew on the wet and dry mill. Gustavo is the agronomist responsible for the Boa Vista farm and one of the most knowledgeable and informative guys I’ve ever met. Talking to him about growing, nursing, pruning, maintaining and protecting coffee trees taught me more than any book I’ve read on the subject(s). Sidney was also kind enough to show me around the Tabuões farm and especially the very large wet mill they have there.

Gustavo showing a handful of the late harvest

I’m going to divide the account of this trip into three post of which this was the first. And instead of boring you with every little detail about what I did on my trip, I’m going to structure it around what happens on the farm.

Indsendt af

Klaus Thomsen

1 kommentarer

![]()

Tuesday, August 3, 2010

Last cupping session with Jordan!

Indsendt af

Casper Engel

1 kommentarer

![]()